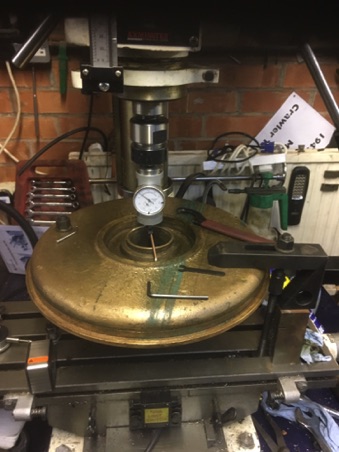

Pump Overhaul

The pump was badly worn. First I bored out the housing to return the bearing surface to round. I then machined the impeller surface and sleeved it to fit the new diameter of the housing. The wear ring diameters were trued up, 0.125" needed to be removed, and then new wear rings turned to the new diameters. Hopefully that will last a good many years more.